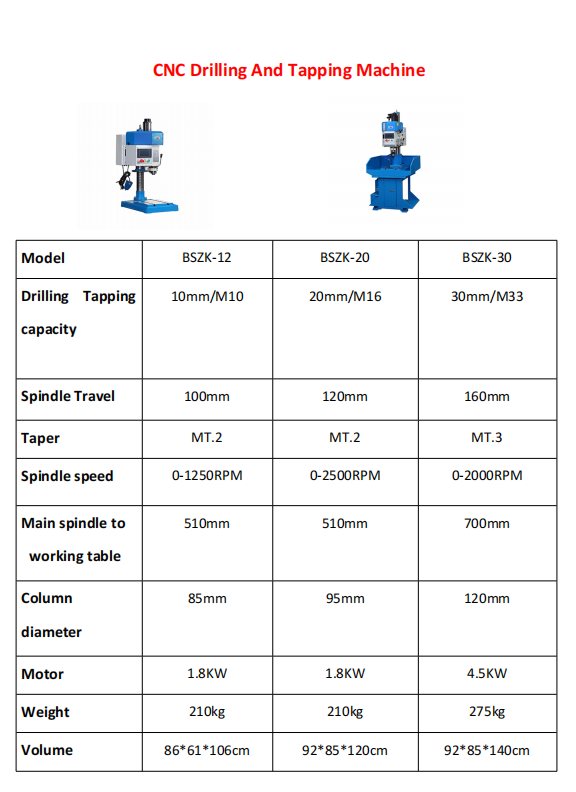

CNC drilling machine

0.01mm persistence

"Failed again!" Lin Mo threw the part in his hand on the operating table fiercely, and the sound of metal collision was particularly harsh in the empty workshop. This was the seventh part he scrapped this week, and every time he failed in the last process.

His eyes fell on the buttons of the drilling machine. This equipment has been in service for a full ten years, and the buttons are not sensitive.

Lin Mo turned on his mobile phone and took out the parts drawings sent by the customer. This is a core component of a precision instrument, requiring a 0.3mm micro-hole to be drilled on the wall of a hole with a diameter of 5mm, and the position accuracy must be controlled within 0.02mm.

"Conventional methods will definitely not work..." Lin Mo muttered to himself. He remembered a case his friend had told him, using CNC machine-assisted processing can greatly improve drilling accuracy. But this solution requires equipment modification.

Lin Mo found Master Chen who could modify the machine. Master Chen stared at the drawings for a long time. "Okay, but it will take three days to modify the equipment." He looked at Lin Mo meaningfully, "You have to pay more."

Three days later, when Lin Mo stood in front of the CNC drilling machine again, his palms were sweating.

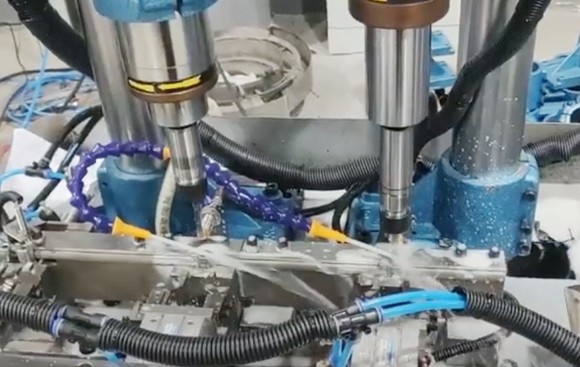

He carefully clamped the workpiece and entered the processing program. As the spindle slowly turned, the machine made a slight hum. Lin Mo held his breath and stared at the data on the display without blinking. After debugging, the machine ran stably and all parameters were within the set range. The CNC drilling machine successfully completed all processing tasks, running smoothly and meeting the accuracy standards. The equipment is running normally, the process is running smoothly, and the production efficiency has been significantly improved.